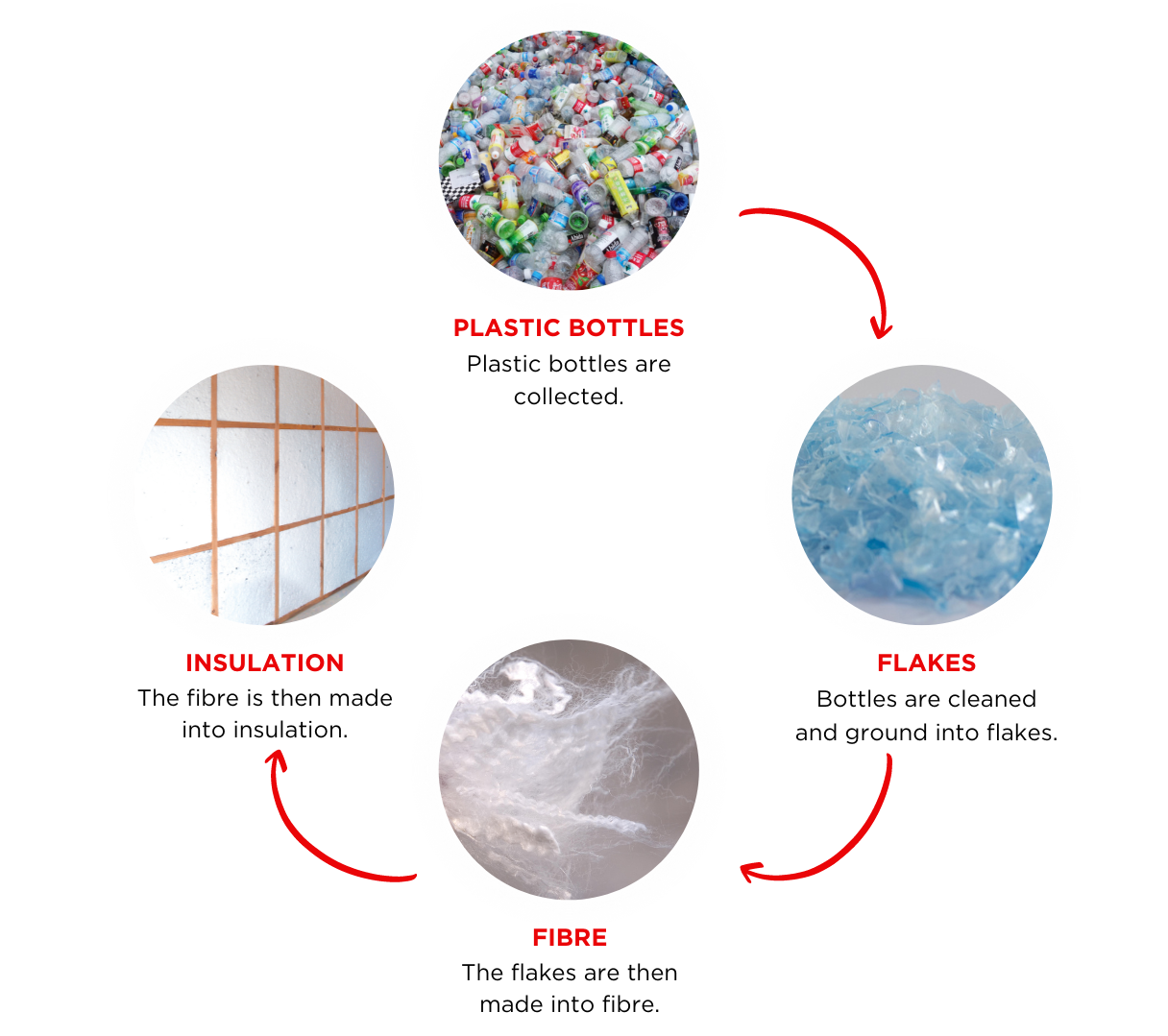

For our Mammoth Modern Insulation, we source the best polyester fibres and take recycled fibre from PET plastic bottles which would otherwise end up in landfill as waste and manufacture it into polyester insulation.

An optimal blend of fibres for each product is created from a mixture of highly technical fibres for extra performance, recycled fibres for sustainability, and bi-component fibres for bonding.

Mammoth polyester insulation creates warmer, healthier homes and buildings. Our zero-waste manufacturing process and the rigorous Eco Choice labelling standards ensure our products meet high environmental performance criteria

Mammoth's thermal and acoustic insulation is made from 100% polyester and uses up to 15,600 recycled PET plastic bottles per 100 sqm*.

Most of our Mammoth products are Eco Choice Aotearoa (prev. Environmental Choice) certified, with 60% of the raw material used being made from fibre manufactured out of recycled PET bottles.

Our commitment to sustainability is paramount to us and incorporated in the way we operate the business, our manufacturing processes and the way we help our customers create warmer, healthier, more energy efficient environments - all while protecting the largest environment of all, our planet.

As a zero waste manufacturer:

We offer a TakeBack scheme for all products and packaging across the country to reduce waste.

Our insulation product is completely recyclable and the product must be uncontaminated and returned to our branch for recycling.

We take clean offcuts back from the market and recycle them back into product. All plastics are baled and returned for recycling. We run it through a purpose built reclaim line where it reopens it back into a fibre form and we use this product as post-consumer recycled fibre. The manufacturer of our product is zero waste.

Read more on our TakeBack scheme here.

Our New Zealand manufacturing plants produce a range of products - our softer blanket form, rigid friction fit segments and acoustic panels.

Airlay manufacturing

Our Airlay sections are manufactured with technology where the fibres are blended together, and then under air pressure, there is a transfer process that blows all of the fibre into a randomised composition rather than a layered effect (as the carded product would deliver). This provides structural properties of the product which enable it to be friction fitted within a cavity by simply squeezing it in place. This friction fit enables a smooth, seamless installation which maximises thermal performance. So confident about it's performance, we had it independently tested. Click here to view the full report.

Carded manufacturing

Our blanket products are made when the fibres are blended, carded and formed into a web which is then layered to create a loft (blanket) of fibres. This is then heated and compressed to the required weight and performance of our product range(s). When we heat the product it is passed through an oven where hot air is circulated and activates a thermo bonding process. This melts the outside sheath of the bi-component fibre which then bonds the fibres together. Compression inside the oven controls the product density and thickness, which is then cooled. The product is then cut to specification, weighed, vacuum packed and labelled.

As part of InZone Industries Ltd, Mammoth Modern Insulation can offer unparalleled service. These services include: